BROMHEAD RING SHEAR APPARATUSThe TORSHEAR apparatus tests the residual shear strength of remolded soil samples. The main advantage of this method compared to direct shear test consists in the continuous shear with a constant area during the entire test long. This method allows us to recreate in the laboratory exactly the field conditions, giving very accurate residual shear strength values. The sample is loaded vertically between two porous stones by means of a counterbalance 10:1 ratio lever loading system. A rotation is imparted to the base plate and lower plate by means of a variable speed motor. The settlement of the upper platen during consolidation or shear can be monitored by means of a sensitive dial gauge or linear transducer bearing on the top of the load hanger. Torque transmitted to the sample is reacted by a pair of matched load measuring rings or load cells. Linear transducer and strain gauge load cells can be connected to the 30-WF6016 GEODATALOG for data acquisition and processing. |

|

CORE TRIMMER AND CUT-OFF MACHINEUsed to obtain rock samples perfectly machined (cube, prisms, etc.) from irregular rock or core pieces. It is supplied complete with a proper vice to hold irregular pieces firmly in place up to 70x140 mm approximately and a “V” device for cores up to 75 mm dia. Longer cores can be machined by turning the sample upside down in the device. The machine also includes a cooling water inlet and transparent cover, conforming to CE requirements, with a switch that stops automatically the machine when opened. The machine can be fitted with either a cutting blade or a double-faced cup wheel for surfacing cylindrical specimen ends. Blade, cup wheel, and water pump are not included and have to be ordered separately. |

|

CASAGRANDE APPARATUS (FOR LIQUID LIMIT)This method is used to determine the amount of moisture necessary for clay-based terrain to move from the plastic to the solid state. The test principle is based on the relationship between the moisture content in the soil and the number of impacts required to close a crack made in a soil sample that is 13 mm long (1/2” in ASTM test). |

|

AUTOMATIC MECHANICAL COMPACTORThe Mechanical Compactor automatically compacts and rotates mold after each blow while keeping track of the number of hammer blows and shutting off once a preset number of blows is reached. The start/stop function of the compactor is independent of the counter. The unit can be used to perform standard or modified compaction tests using a 5.5 lb. (2.5kg) hammer with 12" (305mm) height of drop or a 10 lb. (4.5kg) hammer with 18" (457mm) drop. Hammer lift compensates the height of the drop for soil thickness in the mold during compaction. Hammer weight is concentrated at the foot, allowing free fall of the hammer. Hammer changes are made from in front of the compactor. |

|

AUTOMATIC DIRECT SHEAR APPARATUSThe choice of different load capacity ranges from 1kN to 20kN. The system will be delivered with the force transducers that requested it. The system can perform all the options automatically or manually. Consolidation, shear test drained or undrained direct shear and residual. The software's real-time graphical data was taken during the test and subsequently allowed to process and analyze graphically and numerically. The software, at the end of the consolidation process, calculates the speed appropriate to the material to be tested for breakage. All graphics and stored data can be exported to Excel for further processing. It also generates reports in Word format. The speed is selectable from 0.000005 to 9.8 mm / min. Speed ranges can be extended or reduced. UNE 103401, ASTM D 6528, ASTM D3080 / T236, ASTM D2435 / T216 |

|

DIRECT/RESIDUAL SHEAR TEST SET 220VAC METRICDirect/Residual Shear Apparatus 1 2.5” diam. or 60 mm square Shear Box 1 2.5” diam. or 60 mm square Specimen Cutter 1 2.5" dia. or 60 mm square Specimen Extrusion Tool 1 Vertical Dial Indicator 1 Horizontal Dial Indicator 1 Proving Ring 1000lb/4.5kN 1 Weight Set. |

|

PLANETARY BALL MILL PM 100Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to well-proven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times. The PM 100 is a convenient benchtop model with 1 grinding station. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. |  |

FALLING HEAD PERMEABILITY APPARATUSThe soil permeability is a very important factor to study the behavior of soil in its natural condition with respect to water flow. The falling head method is particularly suitable for fine-grained soils such as clay-like or silty soils in the range of 1x10-2 to 1x10-6 cm/s. |  |

CONSTANT HEAD PERMEABILITY APPARATUS

The Constant Head Permeability apparatus is used for testing the permeability of granular soils (sand and gravels). The specimen is formed in a permeability cell and water is passed through it from a constant-level tank. Take off point located along the sides of the permeability cell is connected to three manometer tubes mounted on a panel complete with a meter scale. |

|

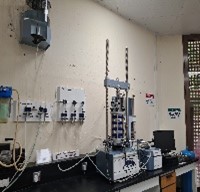

TRIAXIAL TEST APPARATUS

A triaxial test is performed on a cylindrical core soil or rock sample to determine its shear strength. The triaxial test attempts to replicate the in-situ stresses (stresses in the original place the soil sample was taken) on the core soil or rock sample. |

|

CONSOLIDATION AND SWELLING TEST APPARATUS

The typical Consolidation test determines the rate and magnitude of consolidation of a soil specimen. The oedometer consists of a rigid aluminum alloy frame to avoid any distortion under load. The lever arm assembly is supported in precision self-aligning bearings and has three hanger positions for 9:1, 10:1 and 11:1 ratios. The oedometers fit with linear potentiometric transducers, can be connected to Data acquisition unit. |

|

AUTOMATIC SHEAR TESTING APPARATUS

The test determines the consolidated drained shear strength of one specimen of a soil material under direct shear boundary conditions. The specimen is deformed at a controlled rate on or near a single shear plane determined by the configuration of the apparatus. |

|